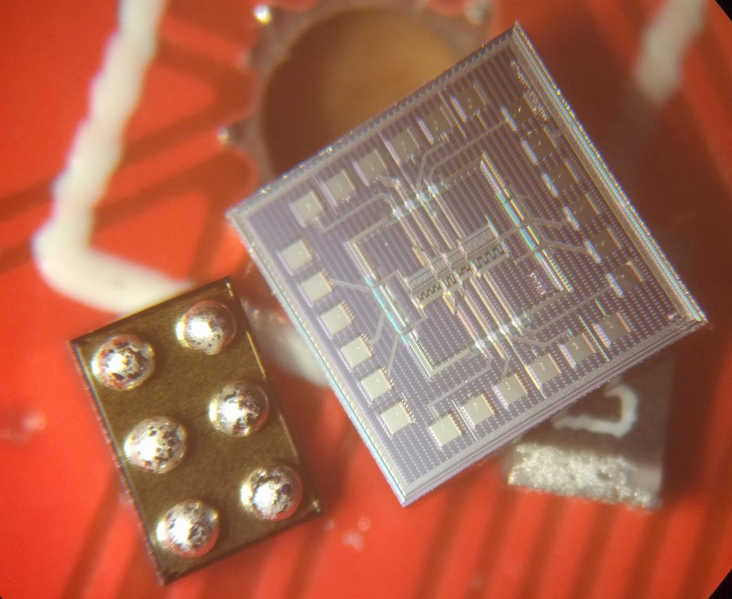

For his Bachelor's thesis, Niklas developed an implant for use in cancer research. The new device is an embedded system dedicated to reading analog signals from a novel, chip-level pH sensitive sensor and transmitting the data via a wireless protocol. Methods of microfabrication such as HDI (High Density Interconnect) circuit boards and 3D printing by stereolithography have been used to achieve a small overall form factor.

The electronic design was optimized for minimal energy consumption to achieve sufficient battery lifetime from a button cell. The circuit, as well as the package principle, can be adapted for other sensors as a flexible platform for small wireless implants. A novel PEEK housing, combined with an o-ring seal for the sensor die, provides high reliability as required for medical applications.

More information: https://github.com/NiklasFauth/sensor-implant

While this project was within the scope of Niklas Bachelor Thesis, most of the development was performed using FIBA's technology:

Design, 3D printing and testing of the packaging was performed in-house.

Development and optimization of the sensors electronics, including antenna matching and power profiling, is within our capabilities.

We are not afraid of chip-level electronics. Connecting and packaging bare dies was performed for this project with great success, verified by a modern xray inspection system.

Please contact us if you need a demonstrator or prototype using chip-level (bio)sensors.

FIBA GmbH

FIBA GmbH